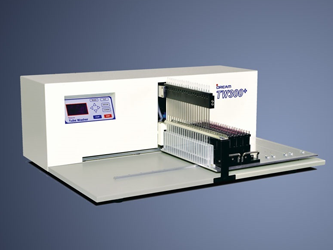

RALS Tube Washer

FAST AND EASY TUBE WASHER OPTIMIZED TO RALS

Procedure Memoring

Frequently used procedures can be memorized

Automatic Recognition

Presence of rack is automatically recongnized by rack sensor. Users do not have to in put the number of rack.

Compatible Rack System - RALS

It is optimized to be used with RALS Compatible Rack which saves time and extra efforts.

Washing Solution

2 kinds of washing solution can be connected at the same time so that users can choose which one to apply.

Washing System

It has dispensing needle and suction needle independently which wash 20 tubes simultaneously.

Waste Management

It collects tracer in a separate tank after washing, which enables easy handling of waste.

Additional availabilities

Control panel displays the status of solution tank and waste tank.

| Specification | Description |

|---|---|

| Dispensing / Suction Needle | 20 / 20 |

| Loadable Carrier / Tube(MAX) | TW300: 5/300, TW180: 3/180 |

| Control Panel | Solution Type (1/2), Dispensing Vol. (1~4ml) Suction Time (~99 Sec.), Washing Time (0~9) |

| Max Tube size (mm) | 12.5 (diameter) |

| Washing solution | 2 types at the same time |

| Rack Detection Sensor Solution Tank Sensor |

Infra-Red Floating Sensor |

| Bead Method Support | Yes |

| Power | 220V, 60Hz |

| Weight | 27kg |

| Dimension (mm) | TW-300 : 820(W) x 600(D) x 295(H) TW-180 : 580(W) x 600(D) x 460(H) |